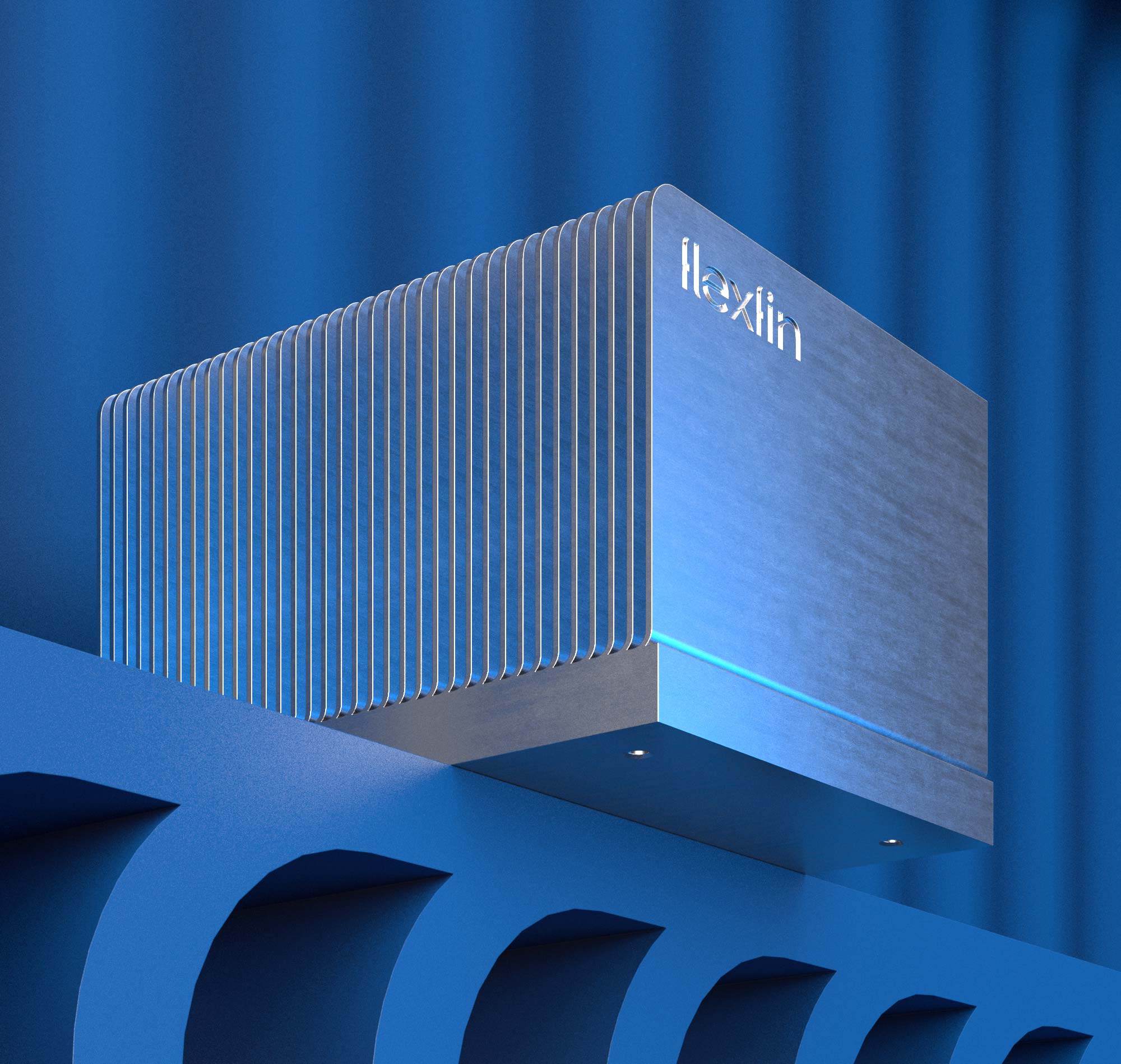

Where classic heat sink construction reaches its limits, Flexfin finned heat sinks open up unimagined freedom.

The best cooling in the smallest space – some would like to take a leaf out of our book, but Flexfin Skiving heat sinks are only available in one piece.

The individual heat sink fins are connected directly to the base without any transition. The base and fins of the Flexfin Skiving heat sinks form a thermal unit.

The fins are peeled from an aluminum block of alloy series 1,000 (e.g. EN AW-1060) or series 6,000 (e.g. EN AW-6063). The thermal conductivity of aluminum is optimal and is up to 230 W/mK. If higher heat dissipation capacities are required, copper (Cu1100) can also be used as the base material.

Compact and flexible

The compact one-piece design makes the heat sinks less vulnerable, as no additional material is used for the connection from the base plate to the individual fins. With the same surface area, the heat sink is lighter and saves material costs.

There is no contact resistance, as is the case with heat sinks with pressed, soldered or glued-in fins. There is no need to worry about fins coming loose or the joining material ageing. Flexfin Skiving heat sinks from Seifert electronic GmbH are ideal for thermoelectric applications or power modules with high power dissipation.

We manufacture Flexfin Skiving heat sinks exactly according to customer-specific requirements and offer maximum flexibility. There‘s only one thing we won‘t let you talk to us about: every single Flexfin Skiving heat sink is like being peeled out of an egg.

Do you need the smallest possible fin spacing or only have a certain fin height available?

Our design parameters show you at a glance what is possible:

Heat sink width | B | <1.000 mm |

Heat sink lenght | L | <500 mm |

Base thickness | T | <30 mm |

Fin thickness | Lt | 0,15 mm – 1,5 mm |

Fin spacing | La | 0,3 mm – 6,5 mm |

Fin height | Lh | 3 mm - 140 mm |

Your advantages:

- optimum thermal conductivity

- manufactured from a single piece

- flexible fin design (thickness, spacing, height)

- freedom of geometry and design for the cooling dimensions

- large surface area due to high fin density

- high strength with low weight

- low tooling costs enable small batches

- fast prototypes without tool investment

Do you have a specific heat sink requirement? We will gladly advise you!