We cool electronics.

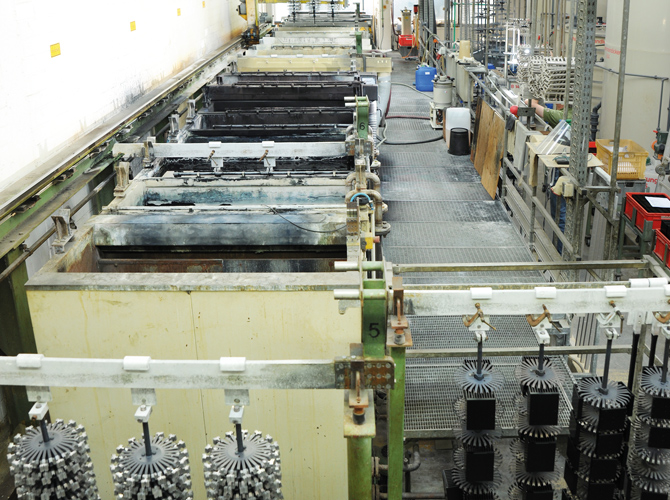

As a powerful partner for a wide range of industries, we now offer a variety of profiles ranging from standard heat sinks to individually machined special profiles. n addition to a large catalog ranging from small PC board heat sinks to high-performance profile heat sinks and finned heat sinks for forced cooling, we produce our heat sinks in almost all desired dimensions and precisely tailored for a wide variety of applications. Our cooling solutions are always individual, dependable and economical.

Seifert electronic has made a name for itself over the years with heat sinks made of extruded aluminum profiles. Our team of more than 50 employees keeps a cool head when faced with any challenge and ensures that our customers’ electronics do not overheat. We work for large and small SME customers worldwide and are represented not only in Europe but also in Asia, South Africa and the USA. We like to be close to our customers and provide personal advice.

Our history

Seifert electronic would not exist without Rolf Seifert. The engineer founded the company in Schwelm in 1965. The first heat sinks produced were extruded profiles for cooling TO-3 components with natural convection. This was followed by cooling profiles for many applications with ever-increasing power ranges going as far as forced cooling with airflow. In the 1970s, fan units, presspack cell cooling and heat conducting products were added to the extensive product portfolio.

Heat exchangers and air conditioning units were added in the 1980s and over time took an increasingly large share of the business. In the late 1990s, the original product division of heat sinks was spun off as an independent company in the course of restructuring. Today, Seifert electronic has its headquarters in Ennepetal and specializes in customized heat sinks made from extruded profiles.

Our future

Our own company history has shown that the continued success, sustained development and future viability of our company requires a willingness to embrace constant change. Just as we want to continuously improve our heat sinks, we also want to do our bit to improve society and the environment. This is why we are committed to our region with a view to the future and the generations to come. We like to work with regional suppliers and support regional associations. In this way, we as a company contribute to sustainable social development for the people in and around Ennepetal.

There is no such thing as 100% clean production. Though in our case, aluminum is 100% recyclable, allowing resources to be reused. We strive to avoid or minimize production-related environmental pollution. We always keep an eye on our CO2 emissions and check the environmental impact of all new products, services and processes.

For us, sustainability also means not just wanting to meet our customers’ requirements with our products and services, but to exceed them every time. Only by keeping this up can we keep our business running and offer future generations reliable heat dissipation for their electronics with our cooling solutions.